Monoamine Oxidase Inhibitor Screening Service

Summary

Before determining the IC50‘s for both Monoamine Oxidase A (MAO A) and Monoamine Oxidase B (MAO B) inhibitors, we performed some initial experiments to establish appropriate assay conditions. We assessed conditions for human MAO A and MAO B. First we titrated the MAO’s using 1 mM p-tyramine as the substrate. From these titrations we decided to use 0.13 U/reaction for the MAO A and 0.25 U/reaction for the MAO B. We next titrated DMSO to determine the highest concentration that would be tolerated by each MAO. The Km of p-tyramine for each MAO was then measured in the presence of the highest tolerable DMSO concentration. Finally, the IC50 for a known MAO A inhibitor, clorgyline, and MAO B inhibitor, pargyline, was measured for each MAO. For the MAO A, we determined the maximum DMSO concentration for the test compounds to be 10 v% (final reaction concentration of 0.5 v%). We determined the p-tyramine Km to be 55.6 ± 3.7 mM for MAO A and 24.1 ± 4.8 mM for MAO B. Using 55 mM p-tyramine, we observed an IC50 = 11 nM for clorgyline for the MAO A. Using 24 mM p-tyramine, we observed an IC50 = 404 nM for pargyline for the MAO B.

Results

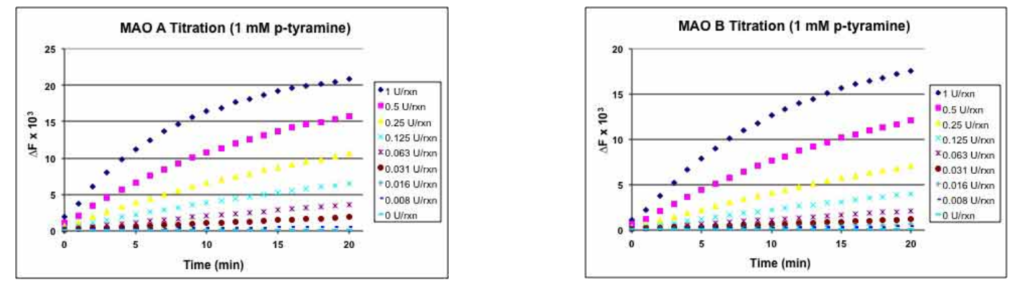

MAO A and MAO B Titrations

In order to determine an appropriate amount of MAO to use for the IC50 determinations, we titrated each MAO. The MAO A and MAO B were titrated from 1 U/reaction. Both titrations were performed using 1 mM final [p-tyramine] as the substrate. The MAO’s titration was performed in a black 96-well plate.

From these results we opted to use 0.13 U/rxn for the MAO A and 0.25 U/rxn for the MAO B. At these concentrations the reaction would remain linear for at least 20 mins.

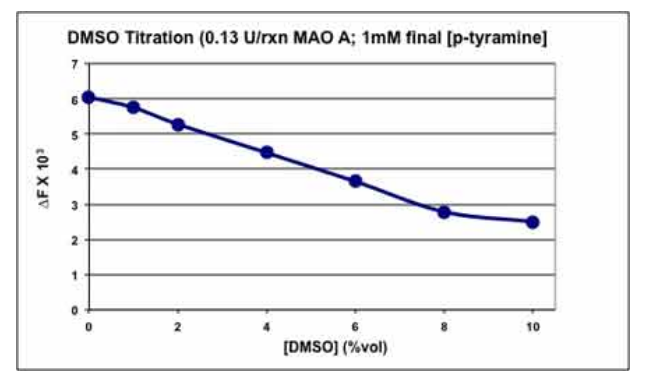

DMSO Titration

In order to determine tolerance for DMSO of the MAO, we ran DMSO titrations for MAO A from 0-10 v%. For these titrations we used 0.13U per reaction for the MAO A. The reaction was initiated by adding 1 mM final [p-tyramine] and was allowed to proceed for 20 mins. We then computed the ΔF (F20min – F0min), which is proportional to the rate of reaction, for each DMSO concentration. The ΔF was then plotted versus DMSO concentration. From these result we discovered that DMSO actually inhibited the activity of MAO. For the MAO A, we decided to move forward with <10 v% DMSO to used to dilute the inhibitors (final <0.5 v/v% per reaction)

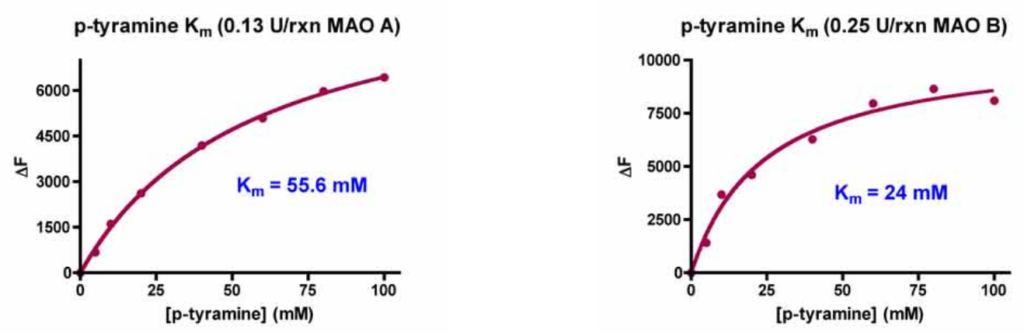

Km of MAO A and MAO B

In order to determine the Km of p-tyramine for MAO A and B, we titrated p-tyramine from 0 – 100 mM with either 0.13 U/rxn MAO A or 0.25 U/rxn MAO B and computed the ΔF (F20min – F0min), which is proportional to the rate of reaction, for each p-tyramine concentration. The ΔF’s were then plotted versus p-tyramine and the Km was computed using Prism 4 (GraphPad Software Inc.). The MAO A and MAO B Km determination was performed in the presence of 0.5 v% DMSO (final reaction concentration). We found the Km = 55.6 mM for the MAO A and the Km = 24 mM for the MAO B.

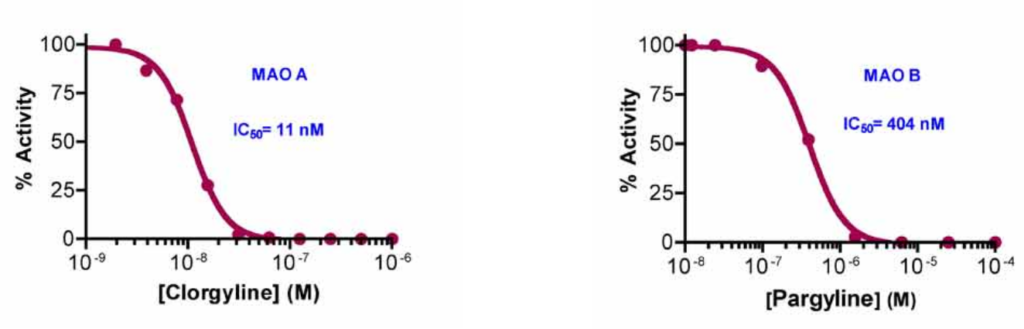

Clorgyline and Pargyline IC50 Determination

The IC50 determination required two steps: 1) 15 min pre-incubation of 45 µL MAO (0.13 U/rxn MAO A or 0.25 U/rxm MAO B) with 5 µL clorgyline in 10% DMSO for MAO A and 5 µL pargyline in 10% DMSO for MAO B, and 2) monoamine oxidase reaction with 0.53 mM final [p-tyramine] for MAO A and 0.23 mM for MAO B for 20 min at 25°C. We titrated clorgyline from 0-0.025 mM and pargyline inhibitor from 0-10 µM and computed the ΔF for each inhibitor concentration. The ΔF’s were then plotted versus the inhibitor concentration and the IC50 was computed using Prism 4 (GraphPad Software Inc.). We observed an IC50 = 11 nM for MAO A and an IC50 = 404 nM for MAO B.

Please email or call 1-510-782-9988 x 2 to request assay service.

Customer Testimonials

"The guys at BioAssay Systems know their science! I had to develop a bioassay for our company and Robert was very quick to respond to keep us up to date. They are knowledgeable and very resourceful. They directed us to one of the bulk suppliers that could give us a really good deal on our active ingredient. They keep very detailed records for our research needs. I would recommend working with BioAssay Systems on your assay development projects!"

"It is a pleasure working together with BioAssay Systems. I brought samples to their Hayward location and received the results in less than 24 hr. The discussion with Robert Z was courteous, open, and with a depth of knowledge. Robert has a PhD from Stanford. Also, Frank Huang, the CEO, had sufficient scientific curiosity to try out our cleanser and provide feedback! This is beyond the call of customer relations. BioAssay Systems is a company with a lot of expertise and a friendly, responsive approach to problem solving. I will enthusiastically continue to work with them to carry out our research."

"I would like to show my appreciation to the Bioassay Systems service team. We are developing an assay to measure the change in lactate concentration of single cell samples using fluorescent microscopy. The BioAssay Systems team was quite helpful in assisting us to optimize their fluorescent L-Lactate assay kit for our unique experimental set-up. The BioAssay Systems team is always friendly and knowledgeable. We know that we can rely on them for fast and professional service."

"While developing biodegradable coatings for Drug Eluting Stents I worked with Bob to develop an accurate, precise and sensitive assay for determining the amount of polymer remaining in tissue. It was a pleasure to work with Bob and his team, they are very thorough, they understand the science very well and they always deliver on time and at the right price. I would highly recommend anyone using BioAssay Systems services in the future."